Generative AI (software capable of producing new content such as text, images, music or animations) has captured the public’s imagination. Many websites offer tools for creating playful visuals or novelty outputs with just a few clicks, but these entertainment-focused applications often fail to address the pressing, real-world demands of modern businesses.

While such generative technologies excel at creativity and rapidly prototyping ideas, Real-Time Edge Intelligence (RTEI) is positioned to have a far greater impact where it counts most, i.e. mission-critical operations. By processing data at the Edge and providing immediate insights, RTEI directly tackles key needs in manufacturing, healthcare, automotive, logistics, and other fields—scenarios in which split-second decisions and reliability are paramount.

Immediate Decision-Making

While generative AI excels at creative tasks, such as producing articles or amusing content—its outputs typically aren’t time-sensitive in physical environments, i.e. they’re not real-time. RTEI, on the other hand, processes real-time sensor data (e.g. temperature, CO2 levels, vibration etc) at the Edge in order to take split-second actions. Typical applications include: worker safety systems, autonomous vehicles and factory robotics. This local intelligence can literally save lives and prevent costly downtime for factory owners.

Operational ROI and Efficiency

Generative AI’s large DNN models are computationally intensive, demanding powerful GPU cloud infrastructure which is power intensive and extremely expensive. Due to the present energy crisis currently gripping the Western world, cutting costs is paramount.

Edge-based intelligence runs on significantly lower-cost hardware (such as Arm Helium microcontrollers), often with lower bandwidth needs and reduced energy consumption, making them more suitable for cost-critical factory automation. Real-time data analysis at the edge can uncover anomalies in machinery before they lead to breakdowns or defects. This proactive approach significantly reduces downtime and waste—outcomes with immediate, tangible returns on investment (ROI).

Industry 5.0 Alignment

Industry 5.0 highlights collaboration between humans and machines, with an emphasis on personalization and sustainability. RTEI facilitates swift, localized decisions that keep production lines adaptive, safe, and responsive to human input—enabling a true fusion of human creativity and machine efficiency.

Workers can use Augmented Reality (AR) glasses or even other wearable devices to receive real-time insights on equipment performance or process instructions. By leveraging local analytics, these tools remain functional and effective mediums in areas with poor cloud connectivity—a massive advantage in busy factories or at remote sites with poor Wi-Fi coverage.

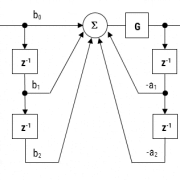

Arm Helium: specialised Edge hardware accelerators

Emerging technologies like Arm Helium – also known as the Armv8.1-M Scalable Vector Extension (MVE) enable complex filtering, sensor-fusion, and inference tasks to be performed at the microcontroller level. This hardware acceleration makes edge-based AI solutions far more powerful than before, paving the way for advanced local inference and localised signal processing for sensor data.

The new M52 core is particularly interesting as it adds Arm’s TrustZone security paradigm to the mix. This innovation allows a single low-power edge device to handle intensive AI tasks (e.g., computer vision), perform DSP operations for filtering IoT sensor data, and provide robust hardware security—all in one solution!

Many of the latest Helium-based microcontrollers also leverage TSMC’s 22nm ultra-low-power semiconductor technology, delivering up to a 50% reduction in power consumption compared to the older 40nm process. As a result, RTEI can now be deployed in battery- or solar-powered devices, extending sustainability and reach without sacrificing performance.

Key takeaways

Generative AI will remain a formidable tool for creativity, rapid prototyping, and entertainment oriented applications. However, its reliance on large-scale cloud resources and the generally non-urgent nature of its outputs limits its immediate impact on mission-critical operations. Real-Time Edge Intelligence (RTEI) by contrast, offers instantaneous, localised decision-making, fortified data security, and tangible cost savings—precisely the attributes demanded by many business owners.

As we enter a turbulent 2025, where rising inflation and energy costs are daily matters of concern, RTEI’s practical benefits will far outweigh the playful allure of generative AI. The evolution of specialised hardware (exemplified by Arm Helium) further confirms RTEI as the essential technology shaping next generation manufacturing, healthcare, logistics and beyond. In this rapidly changing landscape, RTEI is destined to surpass generative AI in real-world importance, defining the future of industrial and operational intelligence.

Leave a Reply

Want to join the discussion?Feel free to contribute!