TED, Tracking Energy Diagnostics

Feel the heartbeat of your machines

Avoid problems with critical assets, prevent downtime

Avoid problems with critical assets, prevent downtime

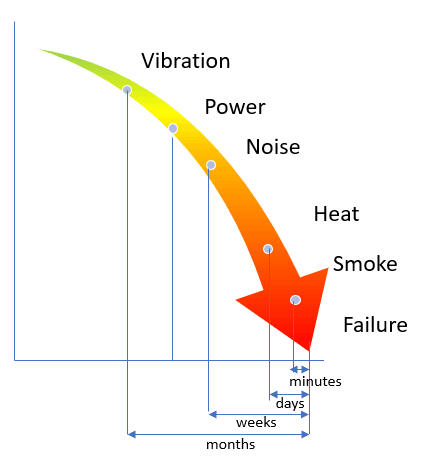

Before a motor fails, the motor sends out signals about its health. Detoritation of your industrial motor condition often start with light vibrations. These are so small that they can only be measured with sensors. We also see power glitches occur. TED, Tracking Energy Diagnostics, gives you insights and early warnings. Using TED will allow you to act in a very early stage, usually months ahead, and repair the damage at the most favorable time.

It starts with vibration in the higher frequency, which is hardly noticeable. When the problems start to get bigger, vibrations arise in the lower frequencies. TED measures these vibrations from 5 kilohertz. This gives you ample time to schedule a repair at the most convenient time

When the problem gets worse, the engine starts to drain more power. Energy costs start to rise considerably

Next, the motor starts to make noise. From then on, it’s usually a matter of weeks before the motor fails. For sound monitoring, an extra option for microphones is possible

If the problems are still not solved, the motor starts to heat up. The chance of failure is increasing and it is usually a matter of days behofe the motor fails. The repair has to take place at a possibly inconvenient time.

Eventually there will be smoke ….

TED measures the most common forms:

Your details will remain strictly confidential, and will not be shared with any other third parties without your prior consent. See the disclaimer for more information.

This gives you ample time to schedule a repair at a convenient time or even to completely replace the motor.

The smart algorithms have the finger on the pulse of the condition of your motor 24/7. They detect ‘normal’ condition, known abnormal patterns and anomalies.