Finite impulse response (FIR) filters are useful for a variety of sensor signal processing applications, including audio and biomedical signal processing. Although several practical implementations for the FIR exist, the Direct Form Transposed structure offers the best numerical accuracy for floating point implementation. However, when considering fixed point implementation on a micro-controller, the Direct Form structure is considered to be the best choice by virtue of its large accumulator that accommodates any intermediate overflows.

This application note specifically addresses FIR filter design and implementation on a Cortex-M based microcontroller with the ASN Filter Designer for both floating point and fixed point applications via the Arm CMSIS-DSP software framework. Details are also given (including an Arm reference software pack) regarding implementation of the FIR filter in Arm/Keil’s MDK industry standard Cortex-M micro-controller development kit.

Introduction

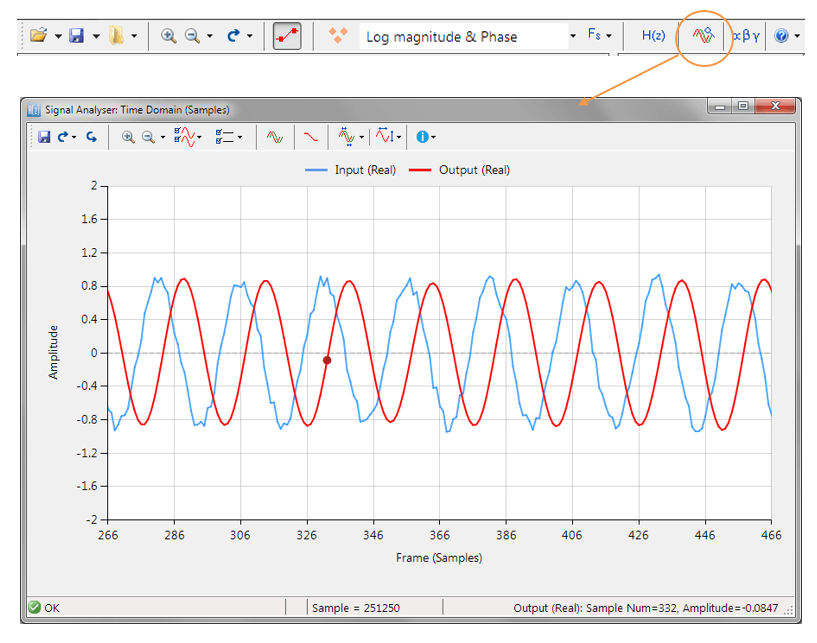

ASN Filter Designer provides engineers with a powerful DSP experimentation platform, allowing for the design, experimentation and deployment of complex FIR digital filter designs for a variety of sensor measurement applications. The tool’s advanced functionality, includes a graphical based real-time filter designer, multiple filter blocks, various mathematical I/O blocks, live symbolic math scripting and real-time signal analysis (via a built-in signal analyser). These advantages coupled with automatic documentation and code generation functionality allow engineers to design and validate a digital filter within minutes rather than hours.

The Arm CMSIS-DSP (Cortex Microcontroller Software Interface Standard) software framework is a rich collection of over sixty DSP functions (including various mathematical functions, such as sine and cosine; IIR/FIR filtering functions, complex math functions, and data types) developed by Arm that have been optimised for their range of Cortex-M processor cores.

The framework makes extensive use of highly optimised SIMD (single instruction, multiple data) instructions, that perform multiple identical operations in a single cycle instruction. The SIMD instructions (if supported by the core) coupled together with other optimisations allow engineers to produce highly optimised signal processing applications for Cortex-M based micro-controllers quickly and simply.

ASN Filter Designer fully supports the CMSIS-DSP software framework, by automatically producing optimised C code based on the framework’s DSP functions via its code generation engine.

Designing FIR filters with the ASN Filter Designer

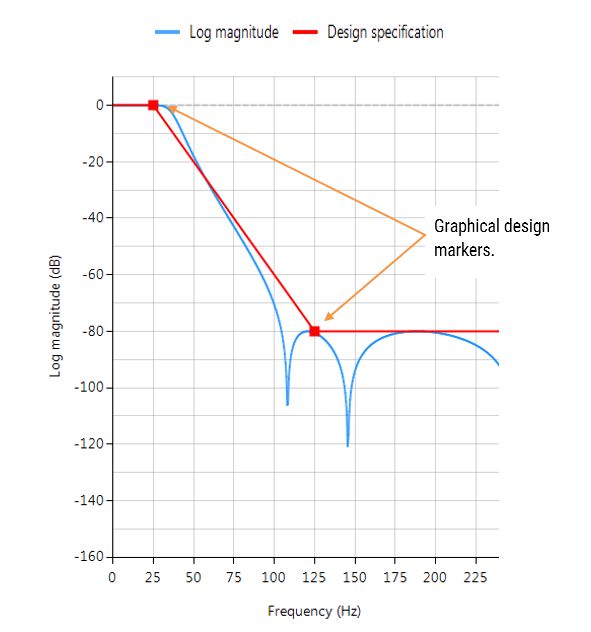

ASN Filter Designer provides engineers with an easy to use, intuitive graphical design development platform for FIR digital filter design. The tool’s real-time design paradigm makes use of graphical design markers, allowing designers to simply draw and modify their magnitude frequency response requirements in real-time while allowing the tool automatically fill in the exact specifications for them.

Consider the design of the following technical specification:

| Fs: | 500Hz |

| Passband frequency: | 0-25Hz |

| Type: | Lowpass |

| Method: | Parks-McClellan |

| Stopband attenuation @ 125Hz: | ≥ 80 dB |

| Passband ripple: | < 0.01dB |

| Order: | Small as possible |

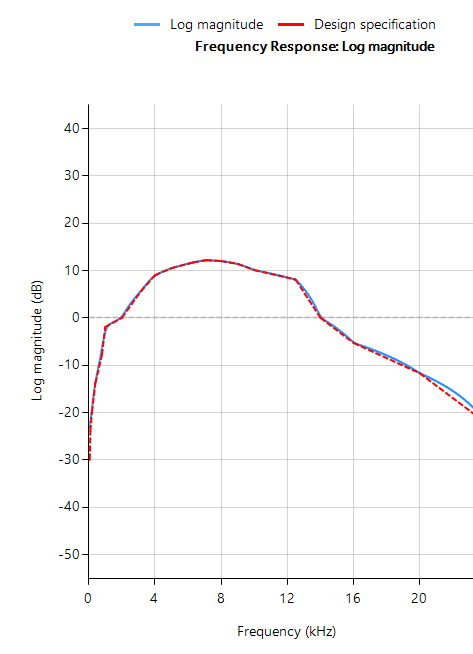

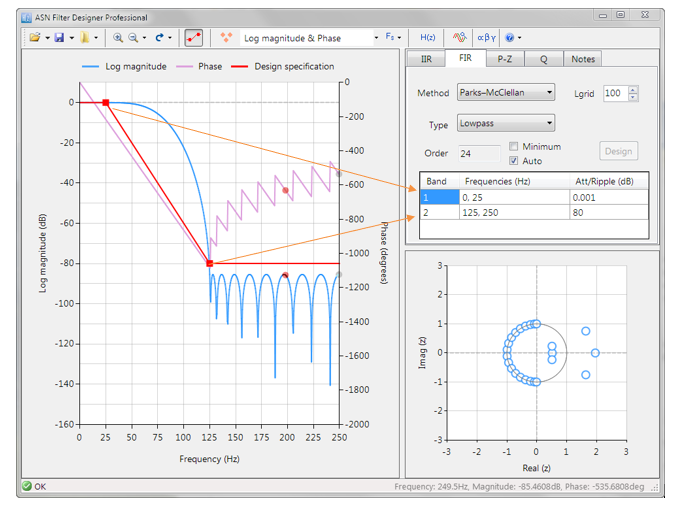

Graphically entering the specifications into the ASN Filter Designer, and fine tuning the design marker positions, the tool automatically designs the filter), automatically choosing the required filter order, and in essence – automatically producing the filter’s exact technical specification!

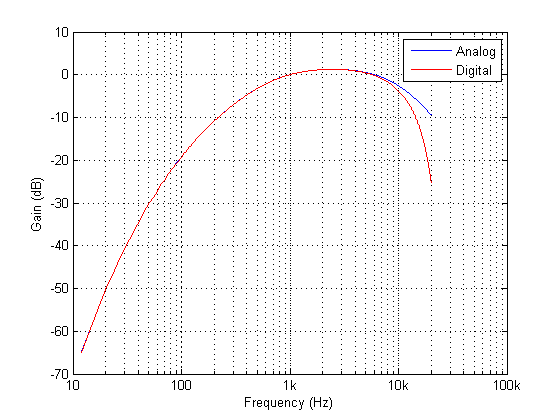

The frequency response of a filter meeting the specification is shown below:

This Lowpass filter will form the basis of the discussion presented herein.

Parks–McClellan algorithm

The Parks–McClellan algorithm is an iterative algorithm for finding the optimal Chebyshev FIR filter. The algorithm uses an indirect method for finding the optimal filter coefficients, that offers a degree of flexibility over other FIR design methods, in that each band may be individually customised in order to suit the designer’s requirements.

The primary FIR filter designer UI implements the Parks-McClellan algorithm, allowing for the design of the following filter types:

| Filter Types | Description |

| Lowpass | Designs a lowpass filter. |

| Highpass | Designs a highpass filter. |

| Bandpass | Designs a bandpass filter. |

| Bandstop | Designs a bandstop filter. |

| Multiband | Designs a multiband filter with an arbitrary frequency response. |

| Hilbert transformer | Designs an all-pass filter with a -90 degree phase shift. |

| Differentiator | Designs a filter with +20dB/decade slope and +90 degree phase shift. |

| Double Differentiator | Designs a filter with +40dB/decade slope and a +90 degree phase shift. |

| Integrator | Designs a filter with -20dB/decade slope and a -90 degree phase shift. |

| Double Integrator | Designs a filter with -40dB/decade slope and a -90 degree phase shift. |

These ten filter types provide designers with a great deal of flexibility for a variety of IoT applications. Design requirements may be simply specified via the use of the design markers. In all cases, the tool will automatically calculate the required filter order to meet the designer’s specification.

The Parks-McClellan algorithm is an optimal Chebyshev FIR design method. However, the algorithm may not converge for some specifications. In such cases, increasing the distance between the design marker bands generally helps.

Other FIR design methods

Designers looking to experiment with other types of FIR design methods may use the ASN FilterScript live symbolic math scripting language. The scripting language supports over 65 scientific commands and provides designers with a familiar and powerful programming language, while at the same time allowing them to implement complex symbolic mathematical expressions. The following functions are supported:

| Function | Description |

| movaver | Moving average FIR filter design. |

| firwin | FIR filter design based on the Window method. |

| firarb | Designs an FIR Window based filter with an arbitrary magnitude response. |

| firkaiser | Designs an FIR filter based on the Kaiser window method. |

| firgauss | Designs an FIR Gaussian lowpass filter. |

| savgolay | Design an FIR Savitzky-Golay lowpass smoothing filter. |

Please refer to the ASN FilterScript reference guide for more details.

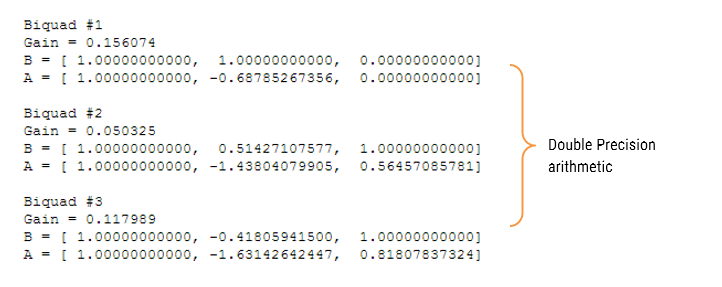

All filters designed in ASN FilterScript are designed using double precision arithmetic in the H2 filter sandbox. An H2 filter must be transformed to an H1 (primary) filter for deployment.

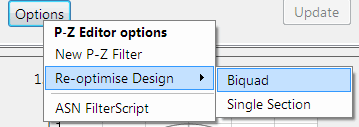

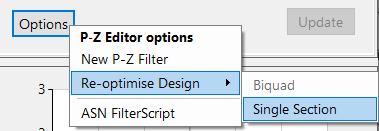

This may be simply achieved via the P-Z options menu:

The re-optimise method automatically analyses and converts the H2 filter into an H1 filter.

Floating point implementation

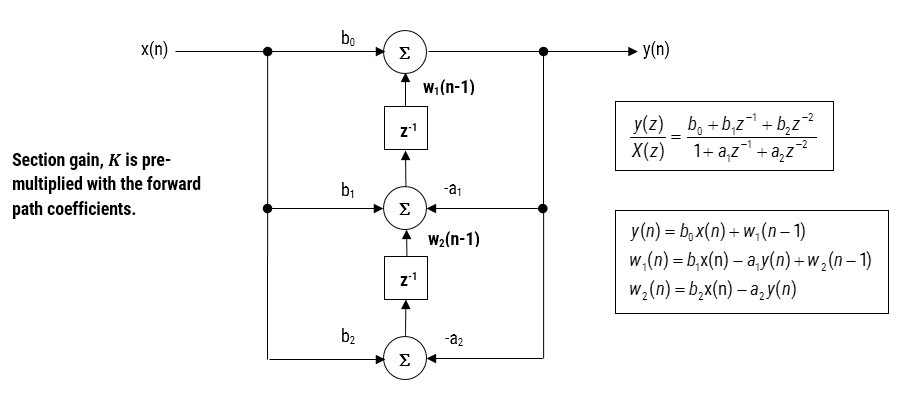

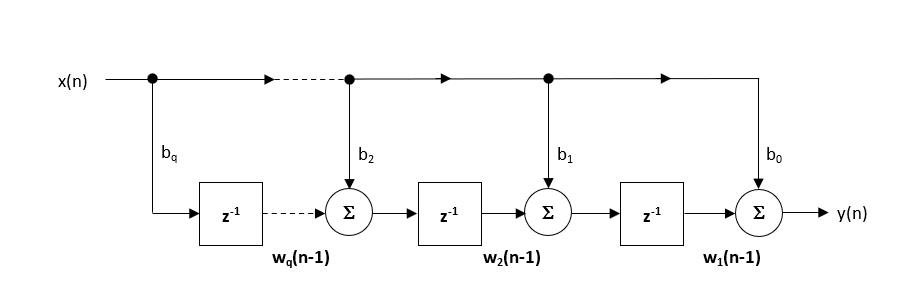

When implementing a filter in floating point (i.e. using double or single precision arithmetic) the Direct Form Transposed structure is considered the most numerically accurate. This can be readily seen by analysing the difference equations below (used for implementation), as the undesirable effects of numerical swamping are minimised, since floating point addition is performed on numbers of similar magnitude.

\(\displaystyle \begin{eqnarray}y(n) & = &b_0x(n) &+& w_1(n-1) \\ w_1(n)&=&b_1x(n) &+& w_2(n-1) \\ w_2(n)&=&b_2x(n) &+& w_3(n-1) \\ \vdots\quad &=& \quad\vdots &+&\quad\vdots \\ w_q(n)&=&b_qx(n) \end{eqnarray}\)

\(\displaystyle \begin{eqnarray}y(n) & = &b_0x(n) &+& w_1(n-1) \\ w_1(n)&=&b_1x(n) &+& w_2(n-1) \\ w_2(n)&=&b_2x(n) &+& w_3(n-1) \\ \vdots\quad &=& \quad\vdots &+&\quad\vdots \\ w_q(n)&=&b_qx(n) \end{eqnarray}\)

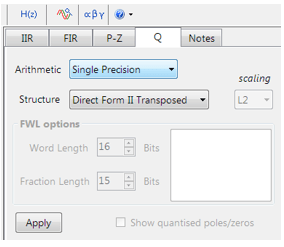

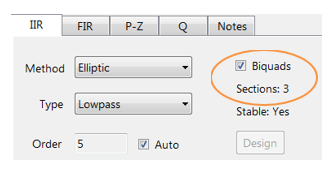

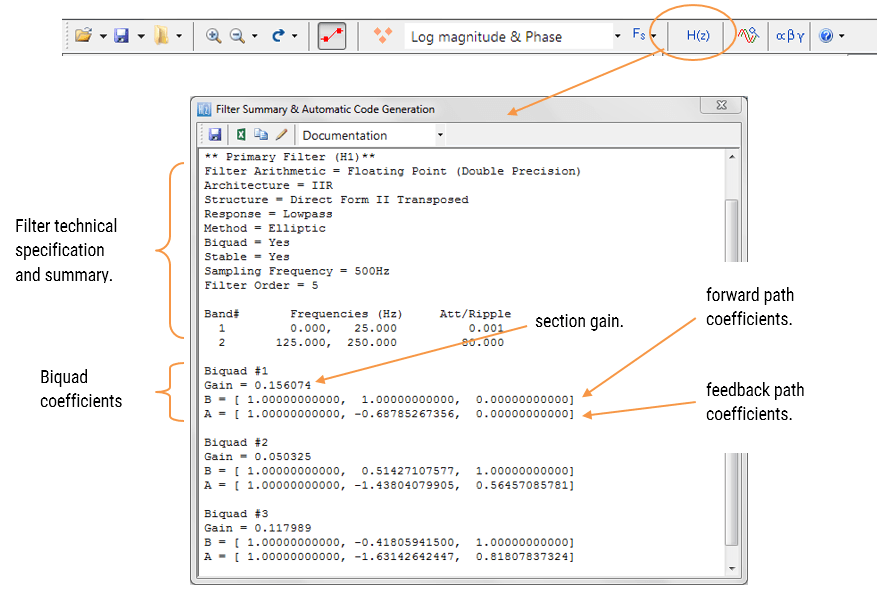

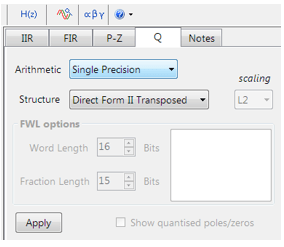

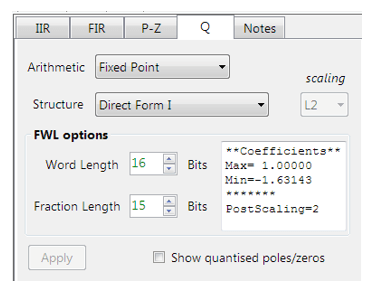

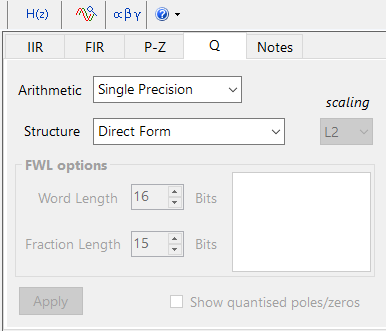

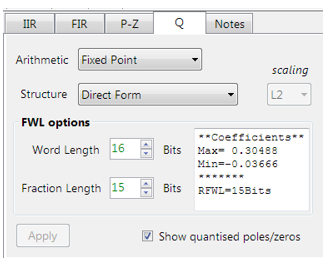

The quantisation and filter structure settings used to implement the FIR can be found under the Q tab (as shown below).

Despite the Direct Form Transposed structure being the most efficient for floating point implementation, the Arm CMSIS-DSP library does not currently support the Direct Form Transposed structure for FIR filters. Only the Direct Form structure is supported.

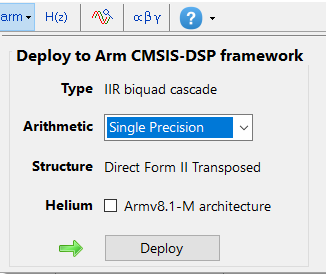

Setting Arithmetic to Single Precision and Structure to Direct Form and clicking on the Apply button configures the FIR considered herein for the CMSIS-DSP software framework.

The optimised functions within the Arm CMSIS-DSP framework currently support Single Precision arithmetic only.

Support for Double Precision and the Direct Form Transposed structure will be added in future releases.

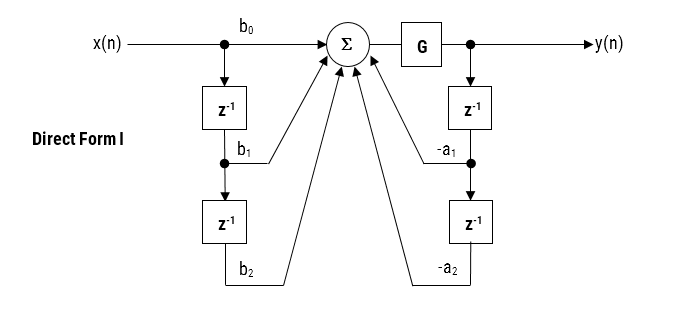

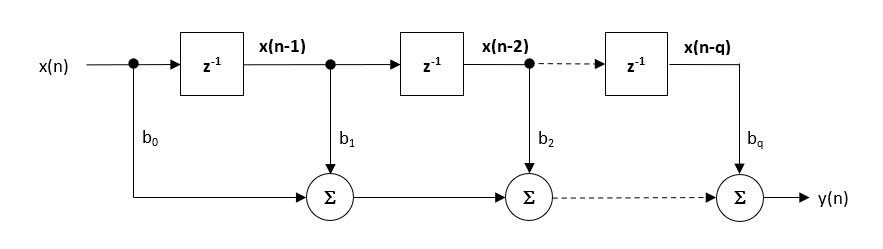

Fixed point implementation

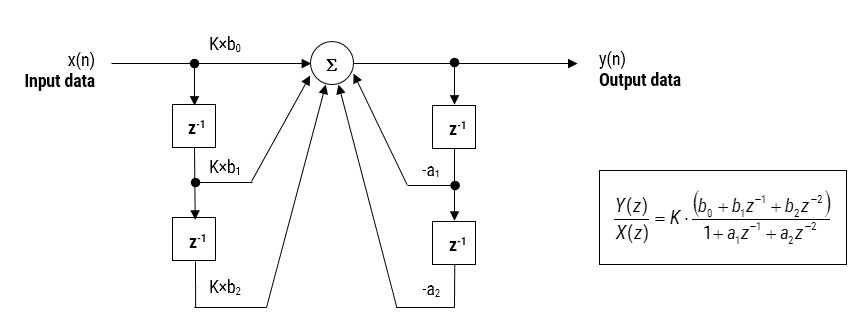

When implementing a filter with fixed point arithmetic, the Direct Form structure is considered to be the best choice by virtue of its large accumulator that accommodates any intermediate overflows. The Direct Form structure and associated difference equation are shown below.

\(\displaystyle y(n) = b_0x(n) + b_1x(n-1) + b_2x(n-2) + …. +b_qx(n-q) \)

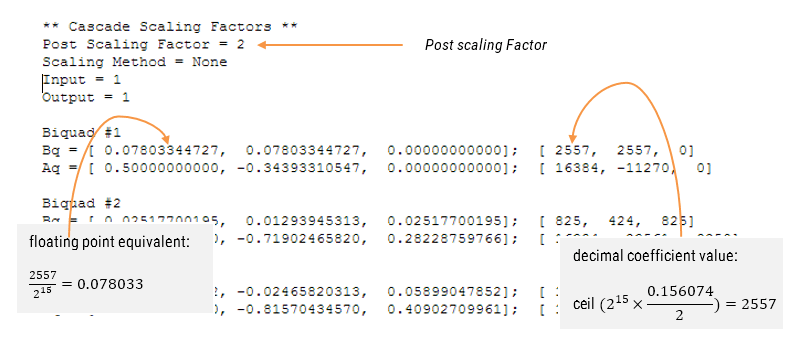

The CMSIS-DSP Framework supports Q7, Q15 and Q31 coefficient quantisation only. The options may be simply specified via the quantisation tab Q as shown below:

The tool’s inbuilt analytics (shown in the textbox) are intended to help the designer choose the most suitable quantisation settings.

As seen on the left, the tool has recommended a RFWL (recommended fraction length) of 15bits (Q15) for the coefficients, which is as required.

The Direct form structure is chosen over the Direct Form Transposed as a single (40-bit) accumulator can be used. The tool’s automatic code generator makes use of CMSIS-DSP’s 64-bit accumulators functions, so that the final C code deployed to a Cortex-M device will not overflow.

Deploying Arm CMSIS-DSP compliant code

The ASN Filter Designer’s automatic code generation engine facilitates the export of a designed filter to Cortex-M Arm based processors via the Arm CMSIS-DSP software framework. The tool’s built-in analytics and help functions assist the designer in successfully configuring the design for deployment.

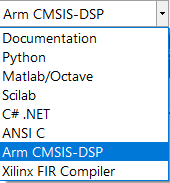

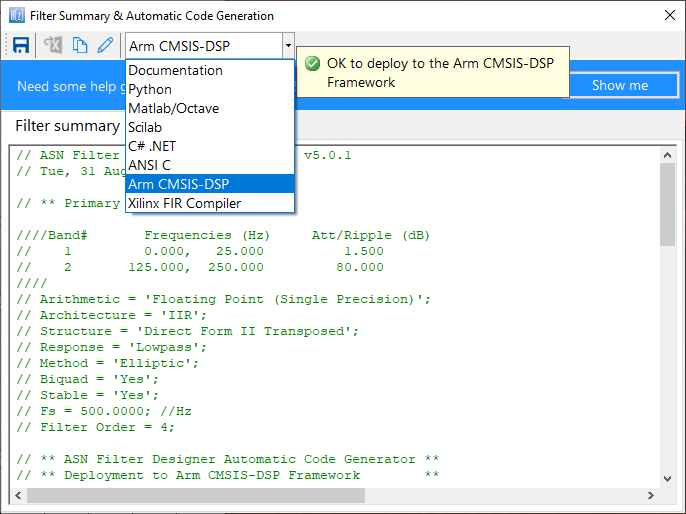

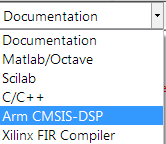

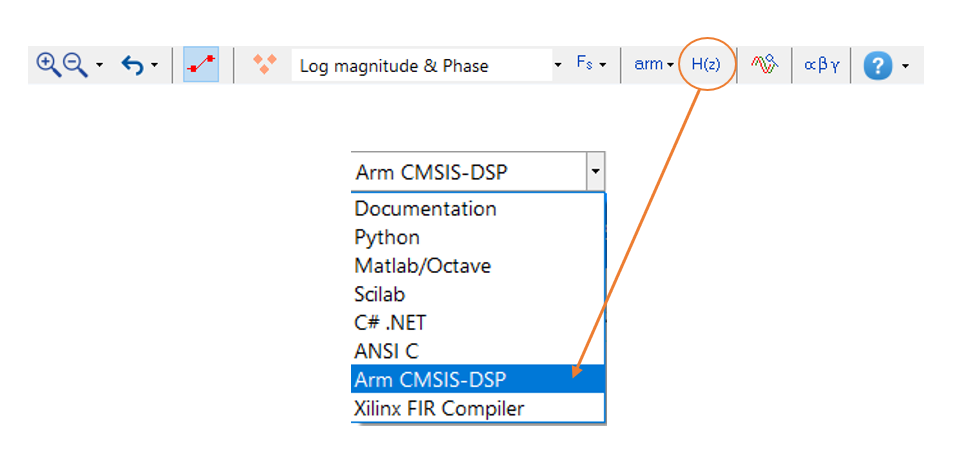

Select the Arm CMSIS-DSP framework from the selection box in the filter summary window:

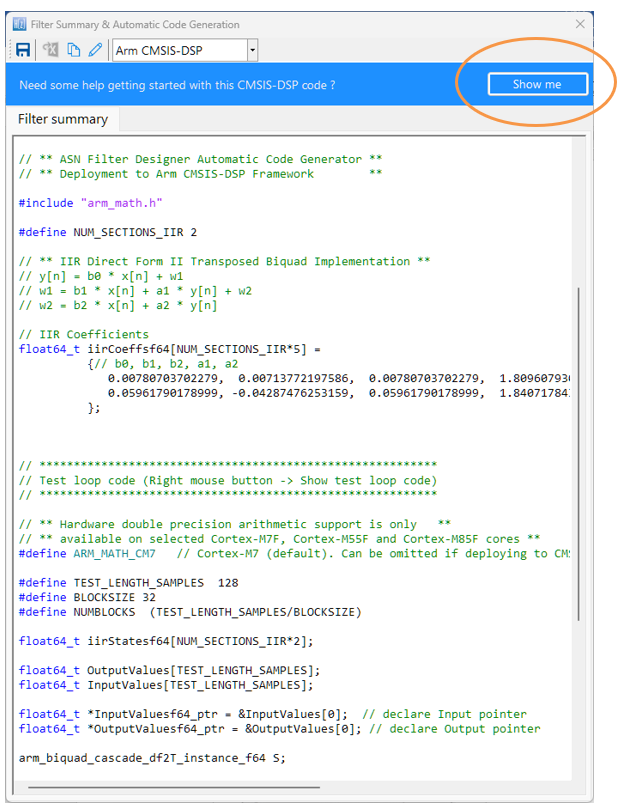

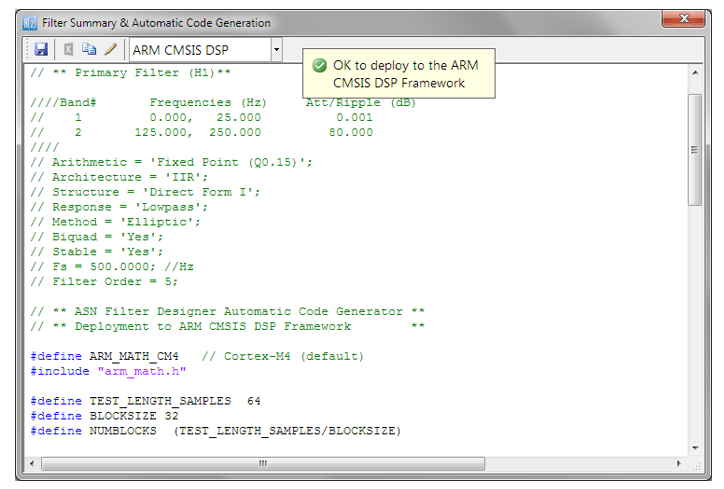

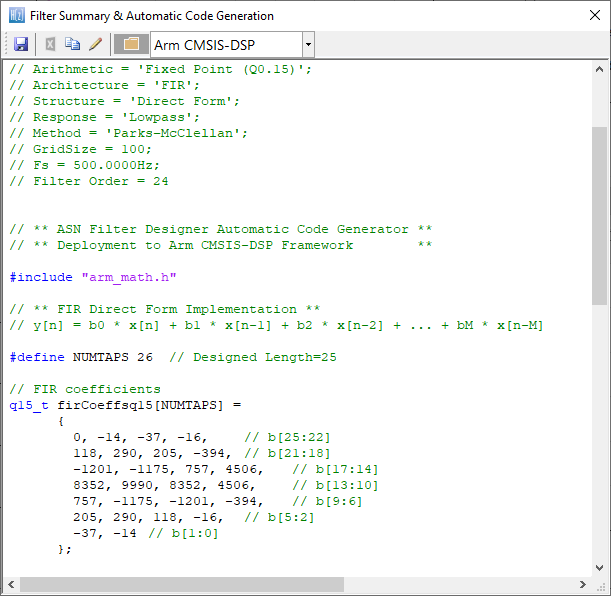

The automatically generated C code based on the Arm CMSIS-DSP framework for direct implementation on an Arm based Cortex-M processor is shown below:

This code may be directly used in any Cortex-M based development project.

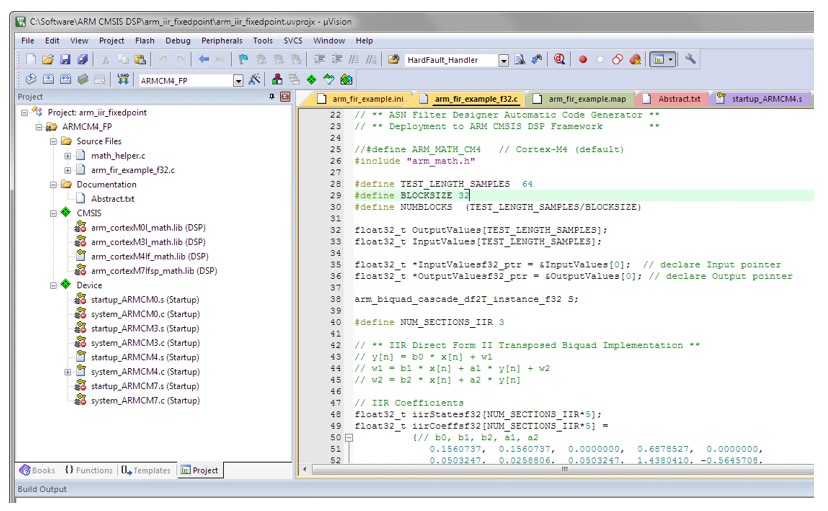

Arm Keil’s MDK (uVision)

As mentioned above, the code generated by the Arm CMSIS DSP code generator may be directly used in any Cortex-M based development project tooling, such as Arm Keil’s industry standard uVision MDK (micro-controller development kit).

The following Arm software pack is available on Keil’s website for using this code directly with Keil uVision MDK.